What is Shirogami Steel?

Shirogami is a type of steel originating from Japan, also known as white paper steel, white paper steel or Yasuki Shirogami.

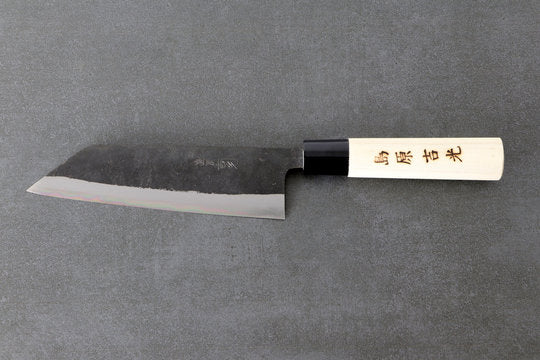

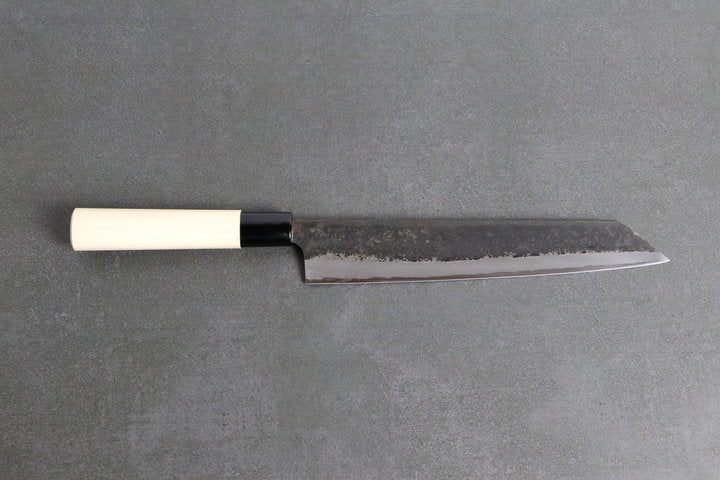

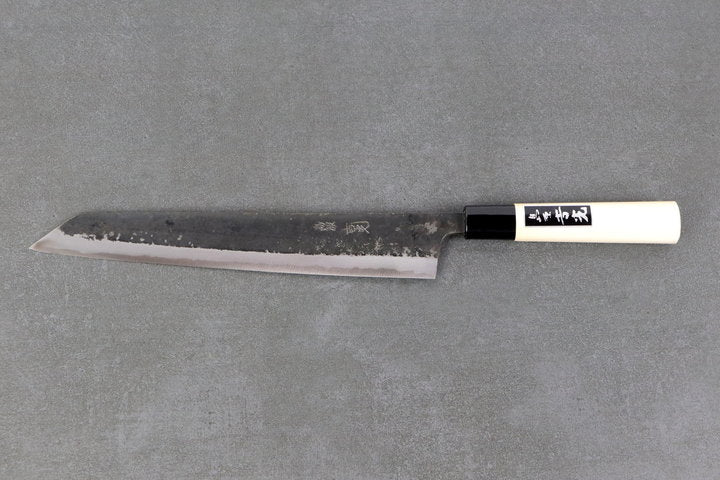

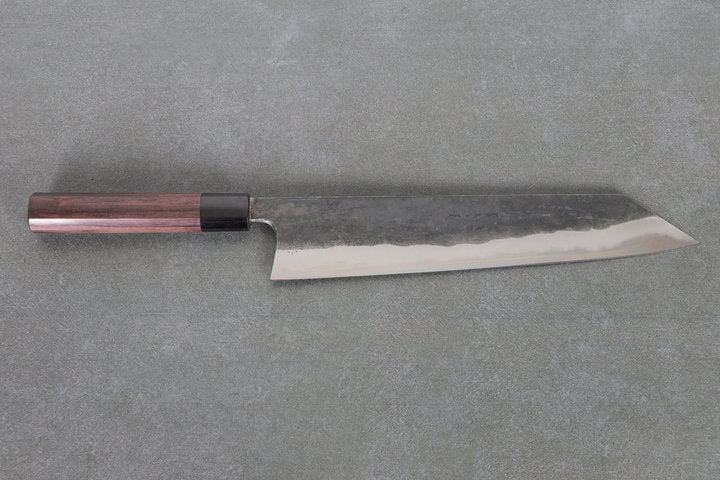

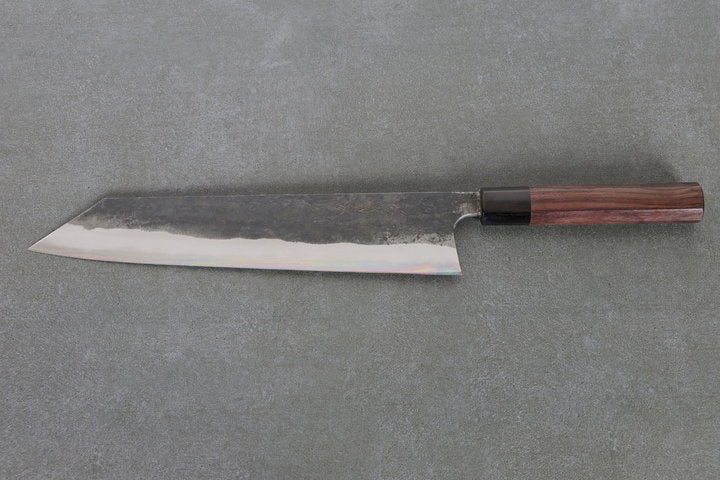

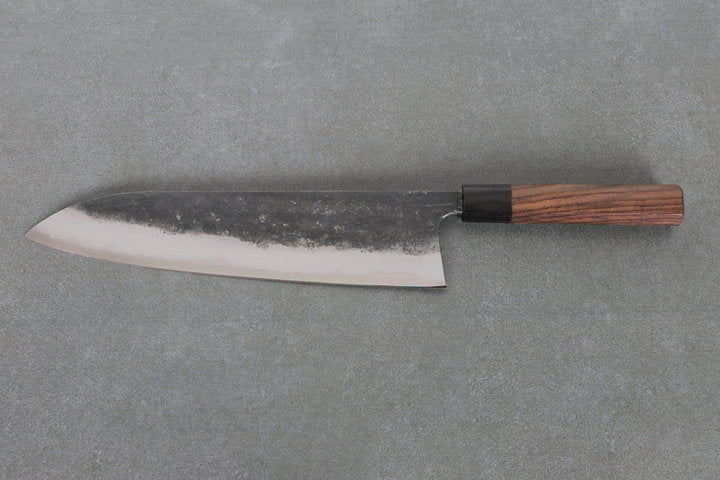

White paper steel is an unalloyed carbon steel with a high degree of purity and the finest martensitic structure, which is why it is popular for fine cutting tools such as chef's knives, scissors, or even sickles and planes. Japanese knives such as the Gyuto, Santoku and Bunka are often forged from this material.

Shirogami for Hamon Knives

White steel is very "clean". Its low alloy composition has a high and pure carbon content. This is good for Hamon blades. Hamon describes a special hardening process of Japanese knives that can be used to apply special patterns on the blade. This technique is based on the principle of different cooling zones when hardening a knife.

Shirogami and Aogami - What is the difference between the steel types?

Shirogami steel (also called White #1) is very similar to Aogami steel, except that the elements chromium and tungsten are not present in White #1 steel. White #1 can therefore be described as a very pure carbon steel (also called carbon steel). Aogami knives are a little easier to sharpen and rust less, but Aogami steel is not quite as hard as Shirogami.

Yasuki Shirogami Composition

The White #2 steel grade (also referred to as Shirogami #2) has a slightly lower carbon content of 1.05 - 1.15% compared to the White #1 steel. White #2 steel does not quite achieve the sharpness and hardness of White #1 steel, but it does exhibit greater edge retention (resistance to sharpening). In terms of susceptibility to rust, White #1 and White #2 are comparable and appropriate care should be ensured in any case.

Shirogami Knife Characteristics

Shirogami knives made of 3 layers of steel combine many good qualities that a good chef's knife needs. The blade can be ground extremely sharp and can stay sharp longer. A grinding with a 13 degree angle is possible, so that the cutting edge remains stable. In contrast to stainless steel, the material is much harder and this is noticeable in the sharpening potential of the blade.

If the knife is resharpened, this is easily done with a water stone or grindstone. Depending on the blade length of the knife, the technique and handling should be adjusted when sharpening. How to sharpen a Shirogami 1 knife properly can be found here: Knife Blade Sharpening.

From all-purpose knives to vegetable knives and Japanese knives with small to large blade length, Shirogami 1 and Shirogami 2 is ideally suited. Below is a brief summary:

- Excellent edge retention

- Very high sharpening potential

- Very high hardness (63 - 65 HRC)

- Easy to sharpen

- Regular maintenance required