The steel grades of Japanese cutlery

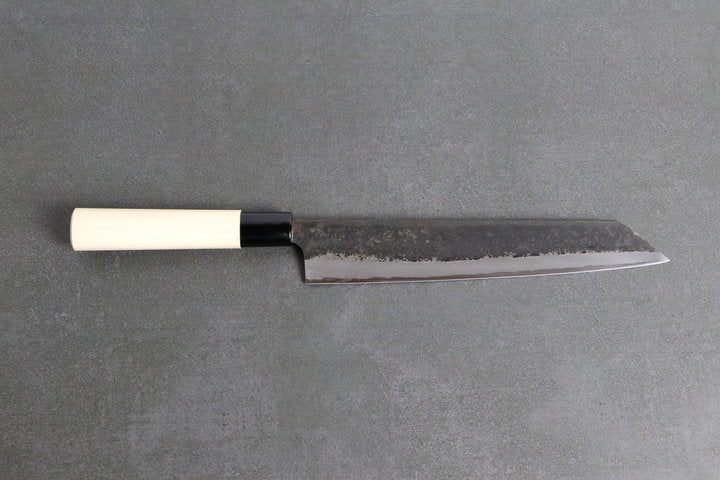

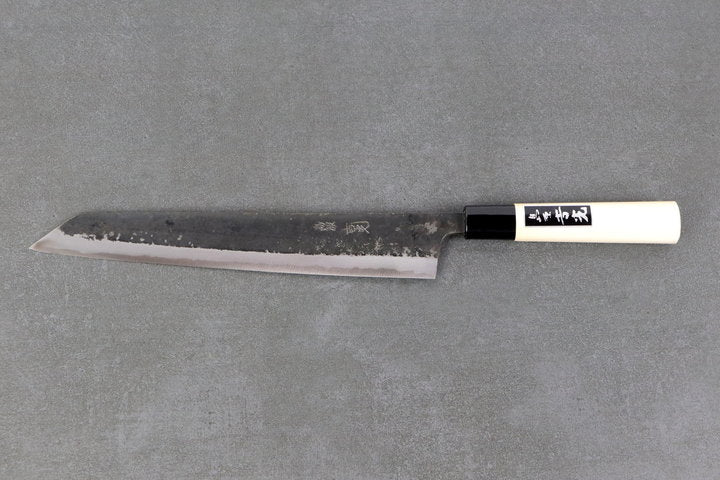

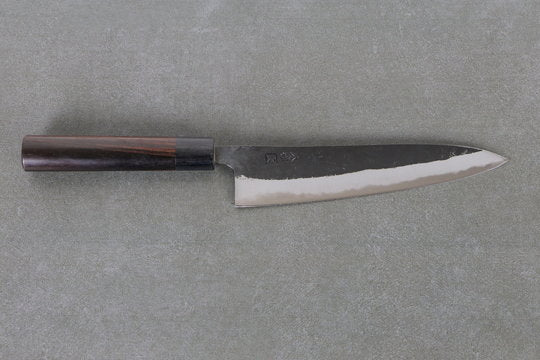

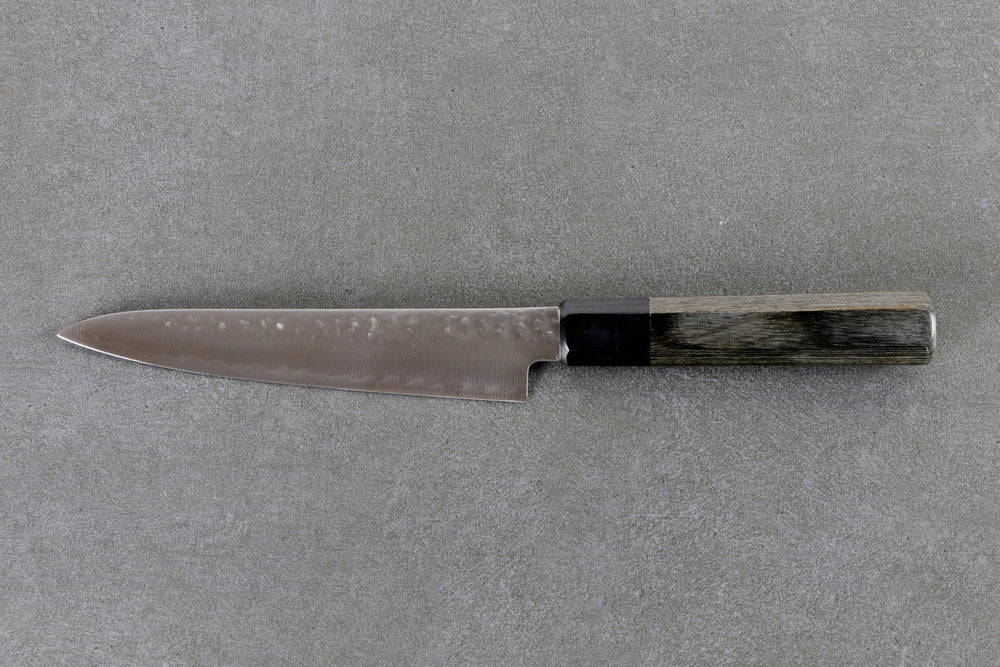

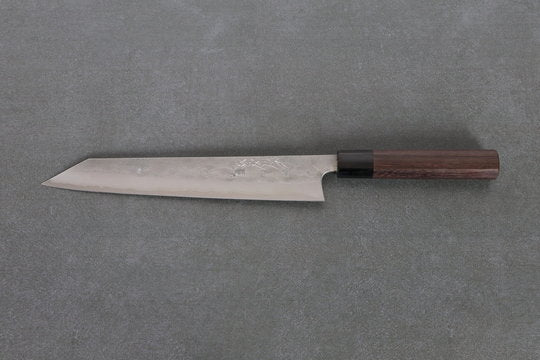

The main component of a knife is the blade with the cutting edge. Various steels can be used for the cutting edge and these should be considered when choosing a suitable knife. A knife can fulfill different tasks, therefore all offered blade shapes and blade steels in our portfolio have their right to exist.

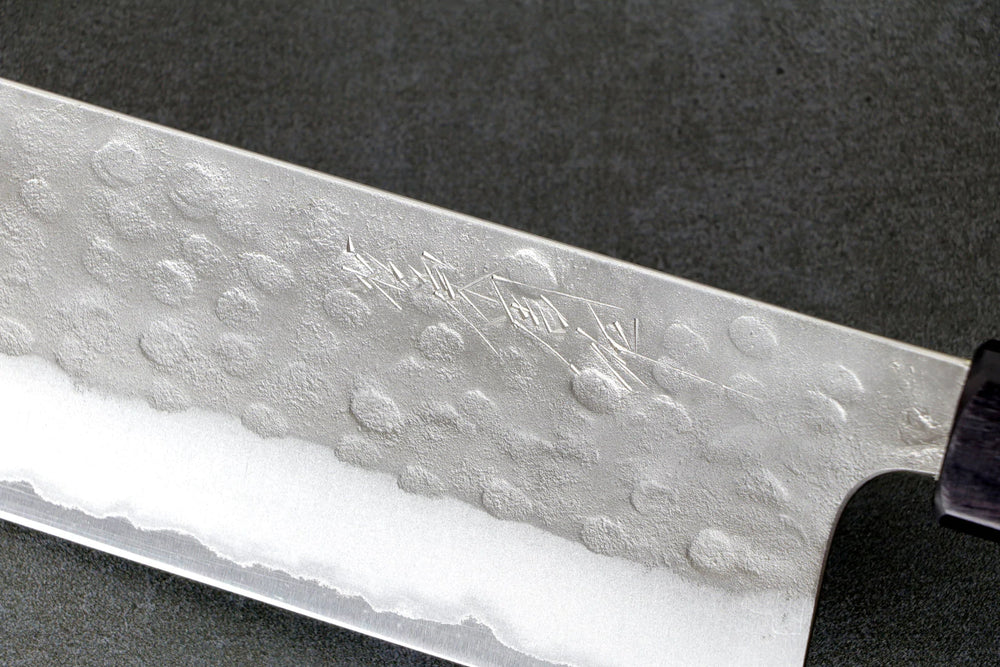

In our product portfolio you will find all common Japanese knife steels from classic carbon steels (Aogami 1, Aogami 2, Aogami Super, Shirogami 1 and Shirogami 2) to high-strength steels (VG10, AUS10, Gin 3 and ATS-34) and pullver metallurgical steels (HAP40 and ZDP189).

Japanese knife blade structure

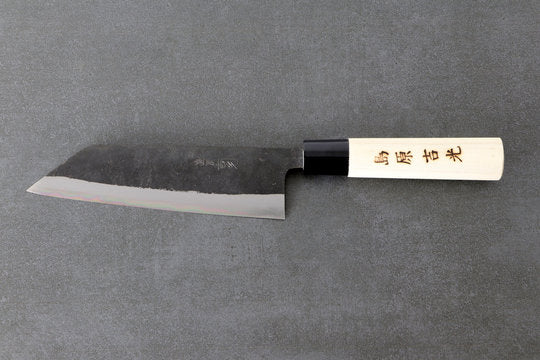

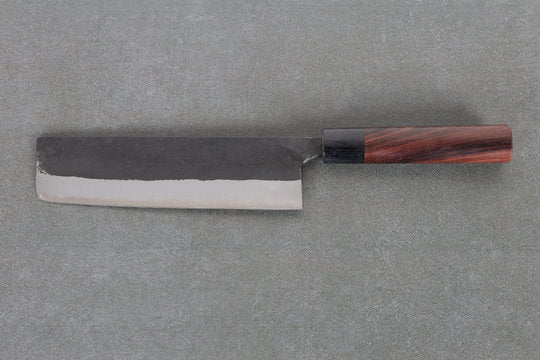

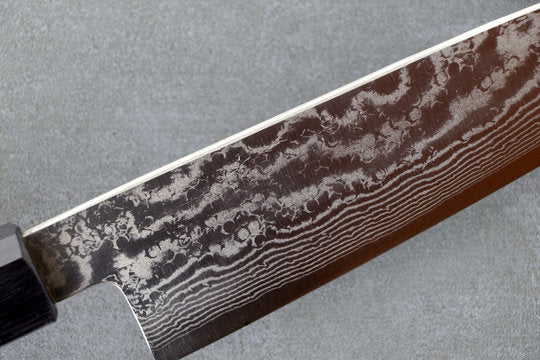

The mostly 3-ply blade construction with a softer outer sheath steel and an inner hard core is available in the Warikomi Awase and San Mai Awase versions.

In Warikomi Awase, the blade steel is completely sheathed with only the cutting edge exposed, similar to the structure of a kebab. In San Mai Awase blade construction, the inner core is also sheathed in another steel, but the construction is similar to a sandwich with exposed blade back and exposed cutting edge.

Another blade construction of Japanese knives is Ni Mai Awase where the cutting steel is plated on one side (like a cheese sandwich) and the blade is mostly ground on one side.

Difference between 3-ply construction and mono steel blades

The 3-ply construction of Japanese knives is also the biggest difference from conventional chef's knives with mono blades, which are often found in German kitchens. The widespread mono steel blade shape, where the complete blade is made of only one material, is not comparable in terms of manufacturing and performance. The 3 layers with an inner hard core that also forms the cutting edge create knife properties that a mono steel blade cannot offer.

Mono blades are usually more flexible and can therefore hardly reach a hardness of more than 58 HRC, which limits the edge retention and maximum sharpness of a blade. Exactly these limitations are overcome by 3-ply Japanese blades in that an outer steel allows the blade a certain flexibility and an extremely hard core on the inside sets the edge retention and maximum sharpness to an extremely high level.

Many types of knives for the market outside of Japan are made of lower hardness knife steels with limited sharpening potential. Original Japanese knives are made of carbon steels, such as the majority of our santoku knives in the store.